China High Pressure Air Compressor

Release time:

Jun 16,2025

Source:

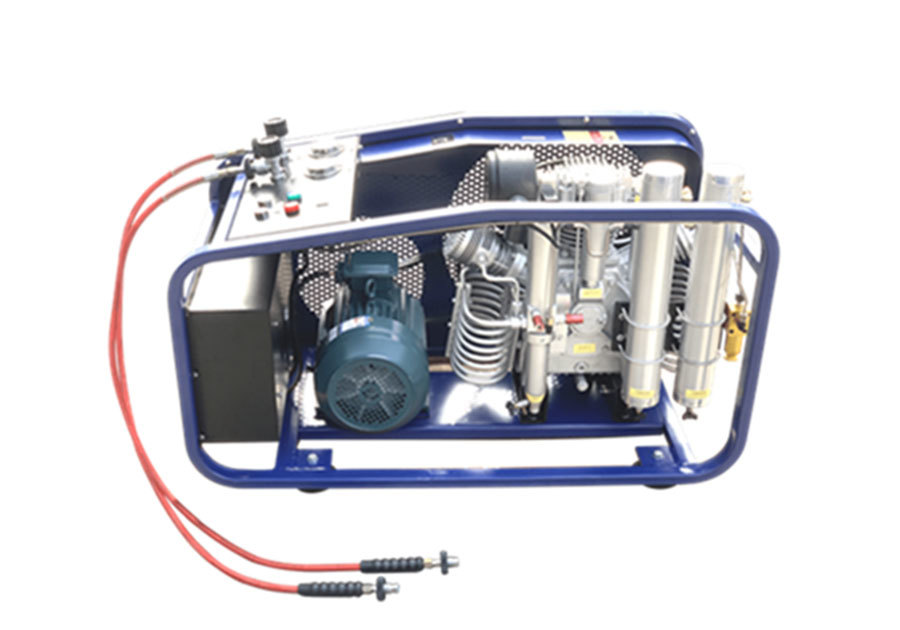

The High Pressure Air Compressor is a cutting-edge solution for applications where standard compressors fall short. With output capabilities reaching up to 4000 PSI, it provides powerful airflow for operations such as cylinder filling, laser cutting, and pressure testing. Its high-performance motor and durable pump design allow for stable pressure generation and low vibration, even during long work cycles.

Product Introduction

Widely used in fire rescue, diving and other industries filling bottles.

Main Specifications

| Structural type | W type |

| Suction pressure | Atmospheric |

| Discharge pressure | 30~33MPa |

| Flow range | 100~910 L/min |

| Motor power | 2.2~18.5kw |

| Cooling Method | Air Cooling |

| Application | Widely used in fire rescue, diving and other industries filling bottles. |

Technical parameters and specifications

| S/N | Model | Motor Power(kW) | Outlet Pressure (MPa) | Flow(L/min) |

| 1 | JR-X100/EM/ET/SH | 2.2-3 | 30 | 100 |

| 2 | MCH6/EM/ET/SH | 2.2-3 | 30 | 80-100 |

| 3 | HBBC-100/EM/ET | 2.2-3 | 30 | 80-100 |

| 4 | JR-W200/ET/SH | 5.5 | 30 | 200 |

| 5 | JR-W265/ET | 5.5 | 30 | 265 |

| 6 | JR-W300/ET/SH | 7.5 | 30 | 300 |

| 7 | JR-W400/ET/SH | 7.5 | 30 | 400 |

| 8 | JR-W400Z | 7.5 | 30 | 400 |

| 9 | JR-X680Z(PLC) | 15 | 33 | 650 |

| 10 | JR-X680Z(PLC) | 15 | 33 | 720 |

| 11 | JR-X810Z(PLC) | 18.5 | 33 | 810 |

The High Pressure Air Compressor is a cutting-edge solution for applications where standard compressors fall short. With output capabilities reaching up to 4000 PSI, it provides powerful airflow for operations such as cylinder filling, laser cutting, and pressure testing. Its high-performance motor and durable pump design allow for stable pressure generation and low vibration, even during long work cycles.

This High Pressure Air Compressor incorporates noise control technology and anti-vibration mounts, ensuring quieter and smoother operation. It’s equipped with precision gauges, pressure regulators, and safety valves to offer full control over compressed air output and system integrity. Its oil-lubricated mechanism also contributes to long service life and low maintenance.

Constructed from corrosion-resistant materials, the High Pressure Air Compressor is built to withstand harsh working environments, both indoors and outdoors. Its portability options, such as wheels and handles, make it convenient to move around job sites.

Offering consistent high-pressure performance and energy efficiency, the High Pressure Air Compressor is an indispensable tool for industrial professionals seeking power, safety, and reliability in one complete package.

Related news

The BOG compressor is specially engineered to handle boil-off gases in cryogenic applications, playing a vital role in LNG logistics and vapor management. It compresses evaporated LNG vapors, commonly known as boil-off gas, to reinject them into the system or direct them for energy recovery, ensuring pressure balance and fuel conservation.

China High Pressure Air Compressor

The High Pressure Air Compressor is a cutting-edge solution for applications where standard compressors fall short. With output capabilities reaching up to 4000 PSI, it provides powerful airflow for operations such as cylinder filling, laser cutting, and pressure testing. Its high-performance motor and durable pump design allow for stable pressure generation and low vibration, even during long work cycles.

Understanding Ammonia Gas Compressors: Key Insights for Manufacturing Professionals

Ammonia gas compressors are essential components in various industrial applications, particularly in the manufacturing and processing of ammonia. Understanding how these compressors operate and their significance can greatly enhance efficiency and productivity in your operations. At the core of an ammonia gas compressor's function is its ability to increase the pressure of ammonia gas, facilitati

Understanding the Role of Ammonia Gas Compressors in Modern Manufacturing

Understanding the Role of Ammonia Gas Compressors in Modern Manufacturing Table of Contents 1. Introduction to Ammonia Gas Compressors 2. Historical Background of Ammonia Gas in Manufacturing 3. Technology Behind Ammonia Gas Compressors 4. Applications of Ammonia Gas Compressors in Industries 5. Advantages of Using Ammonia Gas Compressors 6. Safety Considerations in Ammoni

Understanding Ammonia Gas Compressors: Key Insights for the Manufacturing Sector

--- Ammonia gas compressors play a crucial role in various manufacturing processes, particularly within sectors dealing with refrigeration, chemical production, and environmental control systems. Understanding how these compressors function and their applications can significantly enhance operational efficiency and safety in industrial settings. At its core, an ammonia gas compressor is designed t

Innovative Developments in Diaphragm Gas Compressor Technology

In recent years, the diaphragm gas compressor has become an essential piece of equipment in various industries, from natural gas production to medical and laboratory applications. The diaphragm gas compressor uses a flexible diaphragm to compress gases without the need for lubricants, offering a clean and efficient solution for gas compression.