quality Hydrogen pump

Release time:

Aug 14,2025

Source:

The hydrogen pump features a high-efficiency motor and optimized internal mechanics to reduce operational costs. Its lightweight yet durable construction makes it suitable for both stationary and mobile hydrogen systems. The pump’s adaptive control system allows for smooth adjustments to flow rates, catering to dynamic process requirements. Additionally, its low-maintenance design reduces service intervals, enhancing overall productivity.

Product Introduction

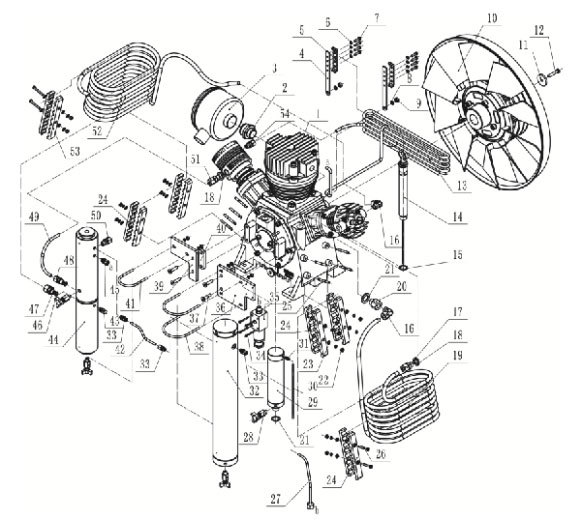

This product is in accordance with the Italian model design changes, optimized for mass production, the last stage piston using a special process, piston ring using the Japanese RIKEN process, all casting products are outsourcing professional casting of large-scale factories, and the product has been on the market for more than 10 years, and has won the praise of users. The product adopts three cylinders, three-stage compression, splash lubrication, interstage safety valve and filtration system.JR-W400 can provide safe compressed air for any industry which needs high pressure pure air source and provide safe compressed air to meet the requirement of human body's respiration. This product is designed, produced and commissioned for acceptance in accordance with the requirements of GB/T 12929-2008 "Marine High Pressure Piston Air Compressor"; the air quality is in accordance with the EN12021 International Breathing Compressor Breathing Standard; JR-W400 is an air compression equipment that compresses air in free state of 1 kilogram (1bar/0.1Mpa), through the step-by-step compression to a gauge pressure of 300kg (300bar/30Mpa) of high-pressure gas, the air flow through the unit in the separator and filter, in addition to the oil and impurities contained in the high-pressure air, but also the inhalation of air containing fine particulate matter (PM2.5) filtered less than 10 micrograms of safety, in line with the standards set by the World Health Organization, so that the discharge of gas is clean and odorless, to provide personnel with a high degree of purification, clean and odorless, Safe and reliable compressed breathing air.

Main parameters

| Model | JR-W400 |

| Working pressure | 30Mpa MPa (300bar) |

| Displacement (suction state) | 400L/min liters per minute |

| Type | W layout - three cylinders three-stage reciprocating piston compression |

| Drive | Electric 380V/50Hz/7.5kw or Honda gasoline engine drive |

| Lubrication | Splash lubrication (food grade lubricant 750-H2) |

| Cooling method | Air-cooled |

| Control mode | Automatic stop |

| Clean air | 1 time air filtration, 2 times oil and water separation, 2 levels of classification air purification |

| Safety devices | Interstage safety valve, pressure maintenance valve, automatic shutdown system, transmission part of the installation of protective cover |

| Package size (L×W×H) | 125×70×92cm |

| Weight | 220kg |

| Filling speed | 6 liters of bottles filled with 30Mpa about 5.5 minutes |

| This product certification | CE certification, MA test report |

| Packing list | Manual, safety inspection report certificate of conformity, inflatable hose and connector 2 sets, machine built-in food-grade lubrication. |

Product Composition and Characteristics

This machine is equipped with automatic shutdown device, free to set the shutdown pressure, equipped with a time running timer, hold the maintenance time.

Can be filled with 2 cylinders at the same time; (1 bottle is recommended to be filled, the filling speed is faster)

High-power all-copper core wire customized motor, stable power output, light starting load.

The protective cover adopts plastic spraying process, not easy to scratch, not rust; (some manufacturers use spray paint, low cost and easy to fall off and rust)

Ultra-strong triangular belt, strong tensioning force, and wear-resistant and high temperature resistant.

Shock-proof pressure gauge 0~5800psi/400bar, accurate pressure value.

Reinforced steel plate base with anti-vibration pads, more stable operation of the equipment.

High-strength nylon cooling fan, better heat dissipation.

Low-voltage copper tubes for better heat dissipation, high-pressure stainless steel tubes to ensure the safety of the output air pressure.

The rotating parts are equipped with protective cover devices, safety valves and automatic shutdown systems at all levels to ensure the safety of operators.

Motor-driven or gasoline engine-driven can be selected to meet the demand for air supply under various conditions.

Equipped with precision air filter (customized silk screen filter element).

2-stage oil-water separator (standard manual sewage, optional automatic sewage) final classified air purification system (standard manual sewage, optional automatic sewage) 2-stage purification, the first water, after the removal of odor; (most manufacturers use 1-stage mixed filtration, saving production costs)

The last stage adopts the piston ring process, wear and tear only need to replace the piston ring; (most manufacturers do not use the last stage of the piston ring process, wear and tear need to replace the piston, the cylinder a complete set of expensive parts to pay for the costs)

The end of the pressure maintenance valve, depth air filtration, and extend the life of the cartridge, and the use of aluminum alloy permanent filter element, replaceable filter element material, save the cost of late use; (some manufacturers do not have a pressure maintenance valve, and the use of disposable filter element, saving production costs, increase the cost of late use)

Cylinders, filter cartridges and other gas contact parts, factory cleaned with alcohol, and the use of food-grade lubricant trial, factory are debugged.

Main applications

|  |

| Submersible Cylinder Filling | Fire Fighting Cylinder Filling |

Firefighting breathing applications: equipped in the fire department gas supply station or a variety of firefighting vehicles, in the fire scene or rescue and relief process, on-site emergency air supply, so that the majority of firefighters in the smoke, gas, steam or lack of oxygen and other environments, breathing to a high degree of purification, clean and odorless, safe and reliable compressed air, thus ensuring that the firefighters can be safe and effective firefighting, rescue, relief, and rescue.

Diving breathing applications: diving clubs, diving enthusiasts, marine aquaculture, marine rescue, shipboard equipment, underground work, fishing, aquaculture, wreck salvage, underwater engineering, water parks, shipbuilding and other industries, to provide divers with highly purified, clean and odorless, safe and reliable compressed breathing air. Under the environment that can not meet the normal breathing air of human body, the air will be filled into the high-pressure cylinder for human respiratory use.

Maximize your hydrogen handling capabilities with our state-of-the-art hydrogen pump, designed for precision and reliability in demanding environments. This pump excels in applications such as hydrogen fueling, energy storage, and laboratory gas supply, offering consistent performance under varying pressure conditions. Its specialized sealing technology prevents hydrogen leakage, ensuring both safety and efficiency. By integrating this hydrogen pump into your system, you can achieve seamless gas transfer with minimal energy loss.

The hydrogen pump features a high-efficiency motor and optimized internal mechanics to reduce operational costs. Its lightweight yet durable construction makes it suitable for both stationary and mobile hydrogen systems. The pump’s adaptive control system allows for smooth adjustments to flow rates, catering to dynamic process requirements. Additionally, its low-maintenance design reduces service intervals, enhancing overall productivity.

To ensure long-term reliability, our hydrogen pump includes advanced filtration and moisture separation features. These protect critical components from contamination, extending the pump’s lifespan. The unit operates with minimal noise, making it ideal for installations in urban or noise-sensitive areas. User-friendly interfaces provide easy access to performance data, simplifying monitoring and troubleshooting.

From small-scale laboratories to large industrial plants, our hydrogen pump offers scalable solutions for diverse hydrogen applications. Custom configurations are available to meet specific pressure, flow, and compatibility needs. Choose this cutting-edge hydrogen pump to enhance your hydrogen infrastructure and support the transition to clean energy solutions.

Related news

Why Choose a Diaphragm Compressor for Your Industrial Applications?

Why Choose a Diaphragm Compressor for Your Industrial Applications? In the realm of industrial applications, selecting the right compressor can significantly impact operational efficiency and overall productivity. Among various options available in the market, diaphragm compressors have gained considerable attention. This article explores the reasons why diaphragm compressors stand out as an excel

Understanding Diaphragm Compressors: Key Insights for Manufacturing and Processing

Diaphragm compressors are specialized devices used to compress gases for a variety of applications in the manufacturing and processing industry. Unlike traditional piston or rotary compressors, diaphragm compressors utilize a flexible diaphragm to create a sealed chamber that compresses the gas. This mechanism allows for increased efficiency and the ability to handle gases that are corrosive or re

Unlocking Efficiency: The Role of Diaphragm Compressors in Modern Manufacturing

Unlocking Efficiency: The Role of Diaphragm Compressors in Modern Manufacturing Manufacturing industries around the world are continually seeking innovative solutions to enhance productivity and efficiency. One technology that has emerged as a game-changer in this quest is the **diaphragm compressor**. These compressors offer unique advantages that set them apart from traditional air compressors,

Understanding Hydraulic Hydrogen Compressors: A Key Component in Efficient Hydrogen Production

Hydraulic hydrogen compressors are specialized devices designed to compress hydrogen gas using hydraulic systems. These compressors play a crucial role in various applications, particularly in the fields of energy production, chemical processing, and even in fuel cell technology. The process of compressing hydrogen is essential for storage and transportation, as hydrogen is typically stored under

Unlocking Efficiency: The Role of a Hydraulic Hydrogen Compressor in Manufacturing

Unlocking Efficiency: The Role of a Hydraulic Hydrogen Compressor in Manufacturing Table of Contents 1. Introduction to Hydraulic Hydrogen Compressors 2. Understanding the Importance of Hydrogen in Manufacturing 2.1 Why Hydrogen is Gaining Traction 2.2 Applications of Hydrogen in Various Industries 3. How Hydraulic Hydrogen Compressors Work 3.1 The Mechanism Behind Hydraulic Compress

Understanding Hydraulic Hydrogen Compressors: Essential Insights for the Manufacturing Industry

Hydraulic hydrogen compressors are specialized machines designed to compress hydrogen gas to high pressures, making it suitable for various applications in the manufacturing sector. Hydrogen is increasingly being recognized as a clean energy source, and its efficient storage and transportation are crucial for utilizing its potential. Hydraulic compressors play a vital role in this process, particu