LNG immersed pump skid

Product Series

Contact Us

Address

Third Floor, Office Building, No. 116 Wenshan West Road, Mishan Town, Wendeng District, Weihai City, Shandong Province,China

LNG station complete equipment

LNG station can be divided into 2 types: skid-mounted LNG station and stationary LNG station.

Keywords:

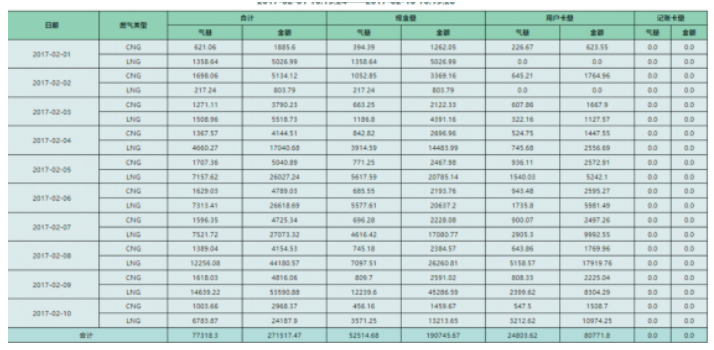

Category:

LNG Station Complete Equipment(test)

E-mail:

E-mail:

1.LNG station complete equipment

Summary

LNG station can be divided into 2 types: skid-mounted LNG station and stationary LNG station. Skid-mounted LNG station is to integrate storage tank, pump skid, PLC control system and LNG dispenser in one skid, which is convenient to transport the full station. Stationary LNG station is to install storage tank, pump skid, PLC control system and LNG dispenser in the station.

Main equipment composition: cryogenic storage tank, LNG cryogenic immersed pump, LNG unloading skid, instrument wind system, PLC control system etc. Main function: LNG unloading, pressure regulating, LNG filling, metering etc. Main

advantages: modular design, high integration level, convenient and efficient installation.

Main functions

Unloading: unload LNG from tank car to storage tank through self-pressurization and pump.

Refueling: refuel LNG to vehicle cylinder through cryogenic pump and LNG dispenser.

Pressure boosting: filling partial LNG into LNG storage tank after vaporized to meet tank setting value

Saturation regulating: pumping partial LNG to vaporizer from storage tank by LNG cryogenic pump, and return to the bottom of storage tank after vaporization, which increases the temperature of LNG storage tank thereby increase the storage tank pressure.

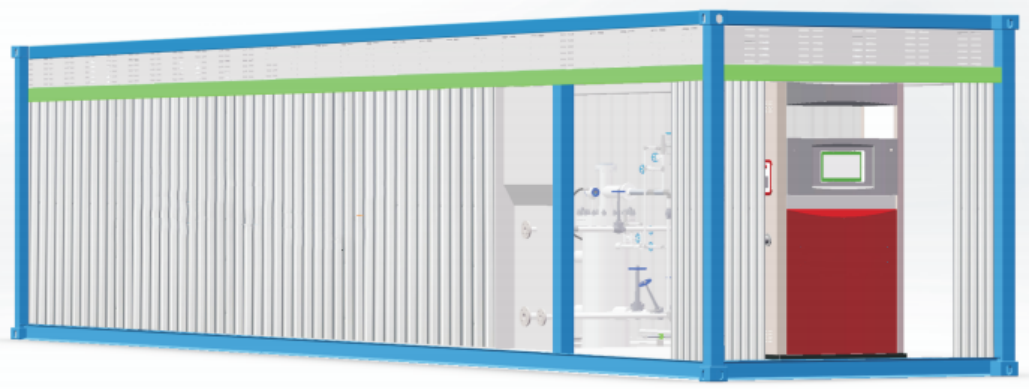

1.1 Skid-mounted LNG station

Summary

Skid-mounted LNG station is the complete LNG refueling system which assembled, tested and debugged in factory. This kind of system integrates LNG storage tank, LNG immersed pump, PLC control system and LNG dispenser in the skid, which is convenient to transport the full station. It can finish unloading, pressure regulating and refueling independently. It can be divided into 2 types: skid-mounted LNG station and container LNG station.

Key Parameter

|

Model |

YN-JYQ-Q30A |

YN-JYQ-Q60A |

|

Working medium |

Liquefied Natural Gas(LNG) |

|

|

Total volume of storagetank |

30m3 |

60m3 |

|

Heatinsulation of storagetank |

High vacuum twine / High vacuum pearlife padding |

|

|

NO.of pumps |

1 unit |

2 units |

|

Max.discharge of pump |

340L/ min |

680L/ min |

|

Operating pressure |

1.6 Mpa |

|

|

Measurin gaccuracy |

±1.0% |

|

|

Pipeline design temperature |

-196℃ |

|

|

Total power |

15KW |

30KW |

|

Noise |

≤55dB |

|

|

Explosive-proof grade |

Exd ⅡBT4 |

|

|

Control mode |

PLC full automatic control |

|

1.2 Stationary LNG station

Summar

Stationary LNG station is the LNG refueling system that is composed of 4 subsystems: LNG storage tank, LNG pump skid, LNG dispenser and PLC control cabinet. Each module finishes assembling, testing and debugging in factory. The station can be put into trial operation after each module connected, installed and debugged simply at site.

Key Parameter

|

Model |

YN-JYQ-AD1A |

YN-JYQ-AD2A |

|

Working medium |

Liquefied Natural Gas( LNG) |

|

|

NO.of pumps |

1unit |

2units |

|

Max.discharge of pump |

340L/ min |

680L/ min |

|

Operating pressure |

1.6 Mpa |

|

|

Pipeline design temperature |

-196℃ |

|

|

Total power |

15KW |

30kW |

|

Noise |

≤55dB |

|

|

Explosive-proof grade |

Exd ⅡBT4 |

|

|

Vaporizer |

300 + 150Nm3 |

|

|

Dimension |

3500*2400*2400( mm ) |

|

|

Control mode |

PLC full automatic control |

|

|

Model |

YN-JYQ-AD1A |

YN-JYQ-AD2A |

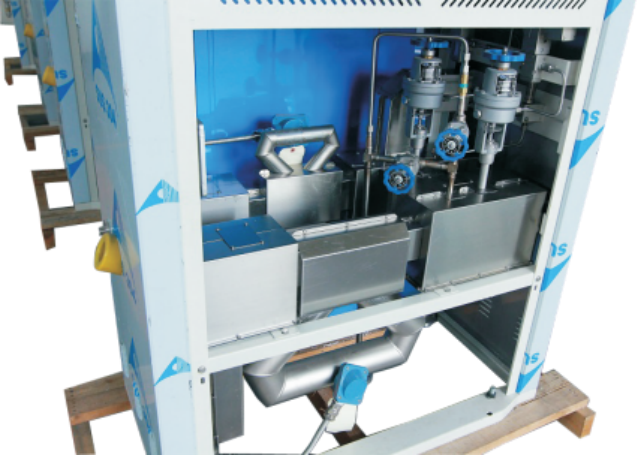

1.2.1 LNG Skid-mounted Pump

Summary

LNG pump skid is to integrate LNG cryogenic immersed pump, vacuum pump pool, vaporizer, vacuum pipeline and valves in the skid, which has functions of unloading, pressure regulating and refueling. Equip with safety precautions such as combustible gas detection, leakage alarm, emergency cut-off etc. Multiple unload mode: pump unload, self-pressurization unload, combined unload etc. Multiple functions: storage tank pressure boost, thermoregulation, instant refuel during unload, dual pump crossed standby application.Pump pool uses high vacuum twine heat insulation, inflow & outflow pipeline use PIR cold insulation mode, which keeps the cold loss to a minimum. Reuse the BOG in storage tank by our particular unloading equal pressure mode.

Advantages

High integration, easy installation, safe and reliable, advanced technological process, cold loss control.

1.2.2 LNG dispenser

Summary

Accuracy of measuring reaches ± 1%. Function of pipeline pressure limiting protection, which realizes overpressure protection through safety valve and pressure sensor. Advanced cold insulation technology - insulation treatment for all inner medium circulation pipelines (including mass flow meter), reduce BOG effectively. Repeated operation is unnecessary as liquid filling interval time is short, which will reduce gas filling waiting time. The operation mode single pumpdual dispensers and “ dual pumps four dispensers come true through interconnected control.

Advantages

High accuracy of measuring、High security、Reasonable technological process Good thermal insulation properties, low loss.

Main functions

● Refuel by non-quantitative and preset volume

● Measuring by mass and volume

● Explosive-proof design: intrinsic safety and isolating safety

● Breakaway coupling

● Save data automatically after power cut, display data lingeringly

● Display unit price, volume and sum with high light backlit LCD

● IC card management, auto settlement and favorable unit price

● Bill printer

● Pressure temperature compensation function

● Stop automatically after refueling completed

● Data transmission communication interface

Key Parameter

|

LNG dispen serseries technical parameters |

|

|

Applicable medium |

Liquefied natural gas |

|

Range offlow |

3 ~80kg/min |

|

Accuracy of measuring |

±1.0% |

|

Working Pressure |

1.6 MPa |

|

Ambient temperature |

-40℃-+55℃ |

|

Pipeline temperature |

-196℃-+55℃ |

|

Ambient Humidity |

≤95% |

|

Ambient Atmosph ere |

86 ~ 110Kpa |

|

Unit of measurement |

Kg、 L、 Nm3 |

|

Minimum scale reading |

0.01 |

|

Single counter Range |

0 ~9999.99 |

|

Totalize range |

99999999.99 |

|

Refueling Hose |

1 inch stainless steel flexible hose(4m/6m) |

|

Gas phase recovery hose |

1/2 inch stainless steel flexible hose(4m/6m) |

|

Filling nozzle |

1 inch special use for LNG dispenser |

|

Gas phase pipe joint |

1/2 inch quick coupling |

|

Power supply |

220V ±15% 50Hz ±1 HZ |

|

Explosive-proof grade |

Complete Machineanti-explosion Exdefbmb ⅡAT4Gb |

|

Rated power |

200W |

2.L-CNG station complete equipment

Summary

L-CNG station is to turn liquefied natural gas (LNG) into compressed natural gas (CNG) through unload, pressure boost, vaporization, lastly refuel to vehicle by CNG dispenser. L-CNG station has the function of CNG main station and substation. The station consists of LNG storage tank, cryogenic high-pressure plunger pump, high-pressure air-heated vaporizer, water-bath type vaporizer (optional), priority panel, CNG cascades, CNG dispenser, process pipe, valves and PLC control system. It is convenient and quick to install with modular design and high integration level.

Key Parameter

|

Model |

YN-JQQ-1500A |

YN-JQQ-2x 1500A |

|

Working medium |

Liquefied Natural Gas( LNG) |

|

|

NO.of pumps |

1unit |

2units |

|

Max. discharge of pump |

1500L/h |

3000L/h |

|

Pressure after pumping |

25MPa |

|

|

Pipe line design temperature |

-196℃ |

|

|

Total power |

≤30KW |

≤65KW |

|

Noise |

≤55dB |

|

|

Explosive-proof grade |

Exd ⅡBT4 |

|

|

Dimension |

3500*2400*2400( mm ) |

|

|

Control mode |

PLC full automatic control |

|

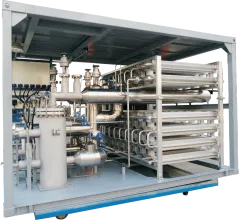

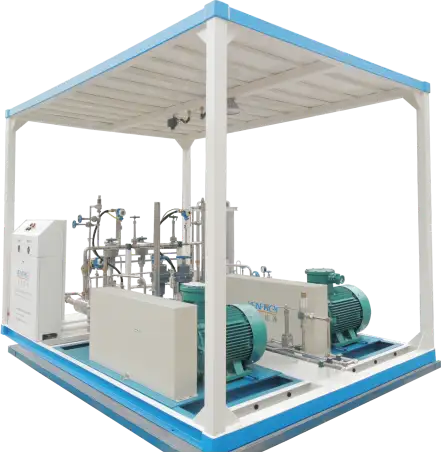

2.1 L-CNG Pump Skid

Summary

Skid-mounted layout makes installation easy. Plunger pump, instrument cabinet, valves and pipelines are integrated in the pump skid. High-pressure vaporizer, EAG vaporizer, water bath electric heater and priority panel also can be integrated in the skid as per customer's requirement. Advantages of skid: install-and-play, convenient and swift.

Equip with safety precautions such as combustible gas detection, leakage alarm, emergency cut-off etc.

Switch freely between dual pumps and high-pressure vaporizer, which improves the heat exchange efficiency. The working mode of single pump and dual pumps switched automatically, which assures equipment run efficiently.

In order to avoid shock transmitting to pump skid, the plunger is integrated into pump skid during transportation and separated from pump skid after pump skid is installed.

Advantages

Safe and reliable、Advanced technological process、Damping and noise reducing

2.2 High pressure vaporizer skid

Summary

High-pressure vaporization skid mainly consists of high-pressure vaporizer, water bath type electric heater, high-pressure EAG vaporizer, sequential control panel, but also equipped with ball valve, safety valve, instrument, combustible gas detector, explosion- proof junction box etc. integrate the decentralized installation equipment in a skid, which has the advantages of convenient transportation and installation, small footprint and so on.

Main parameters

|

High pressure vaporize |

1000Nm³/h~2000Nm³/h |

|

Water bath type electric heater (Optional) |

1000Nm³/h ~4000Nm³/h |

|

Sequential control pane |

1500Nm³/h ~4000Nm³/h |

|

Max. working pressur |

25MPa |

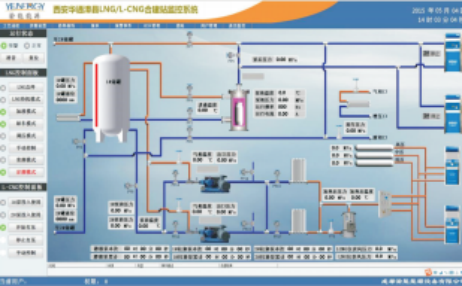

3.LNG/L-CNG combined construction gas station

Summary

LNG/L-CNG combined construction gas station not only can refuel Liquefied Natural Gas for LNG vehicles but also can refuel Compressed Natural Gas for CNG vehicles. Main process flow: unload, pressure regulating, LNG filling, L-CNG pressure measure, CNG filling etc.

Main equipment: LNG storage tank, LNG immersed pump skid, LNG dispenser, LNG cryogenic high pressure plunger pump, high pressure gasification skid, vaporizer, priority panel, CNG storage cascades, CNG dispenser, pipeline and valves etc.

Key Parameter

|

LNG storage tank volume |

60m³、120m³ |

|

NO.of immersed pump |

1unit、2units |

|

Immersed pump displacement |

340L/min、680L/min |

|

Max.working pressure after pumped by immersed pump |

1.6MPa |

|

NO.of plunger pump |

1unit、2units |

|

Plunger pump displacement |

1500L/h、3000L/h |

|

Working pressure afte rpumped by plunger pump |

25MPa |

|

CNG storage cascades |

3.9m3、6m3、8m3 |

|

Total power |

40KW~90KW |

|

Explosive-proof grade |

Exd ⅡBT4 |

|

Control mode |

PLC full automatic control |

|

High pressure vaporize |

1000Nm³/h~2000Nm³/h |

|

Water bath type electric heater (Optional) |

1000Nm³/h ~4000Nm³/h |

|

Sequential control pane |

1500Nm³/h ~4000Nm³/h |

|

Max. working pressur |

25MPa |

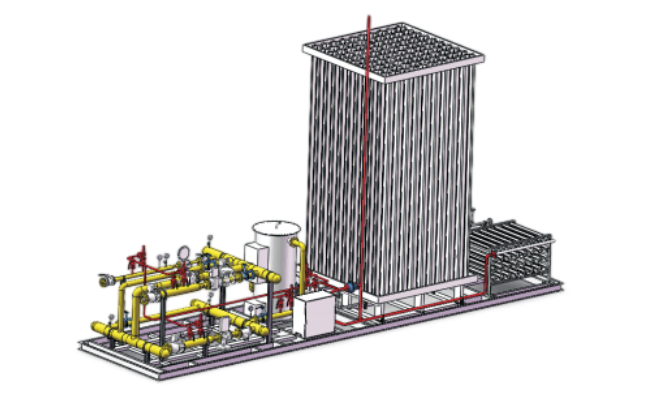

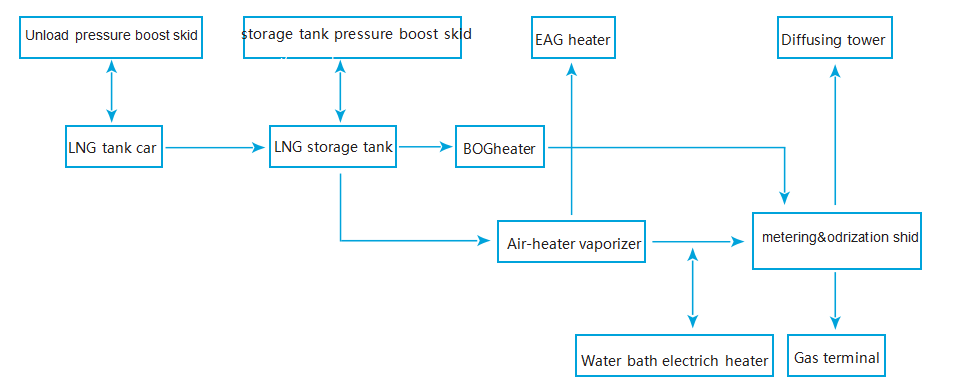

4.L-NG Gasification Station Complete Equipment

Summary

L-NG gasification station is to transmit LNG to natural gas pipeline network and supply natural gas to urban resident ,industrial user and emergency peak shaving after liquefied natural gas through gasification, pressure regulating, metering and oderization.

L-NG gasification station consists of LNG storage tank (LNG Tank Car), unload pressure boost skid, storage tank pressure boost skid, air-heated vaporizer, BOG vaporizer, water bath electric heater, pressure regulating & metering & odorization skid etc.

4.1 Stationary L-NG gasification station

Summary

Stationary L-NG gasification station consists of LNG storage tank, unload pressure boost skid, storage tank pressure boos skid, air-heated vaporizer, pressure regulating & metering & odorization skid and PLC control system. Each module assembled in factory and tested, debugged individually, it can be put into trial operation after simple connection, installation and debugging of each module.

4.2 Integral Skid-mounted L-NG Gasification Station Equipment

Summary

Integral Skid-mounted L-NG gasification station is to integrate LNG storage tank, storage tank pressure booster, EAG heater, air-heated vaporizer, pressure regulating & metering & oderization system and PLC control system in the skid, assembled, testing and debugging in factory, it can be come into use after arriving at the site. Feature: small occupation area, agility of movement.

4.3 Skid-mounted L-NG Gasification Station Equipment

Summary

Skid-mounted L-NG consists of LNG storage tank, vaporization & pressure regulating & metering & oderization system (integrated PLC control system) and unload pressure boost skid, each module assembled in factory, testing and debugging individually, it can be come into use after simple installation & connection. Feature: small occupation area, agility of movement.

5.Marine LNG complete equipment

5.1 Marine LNG complete equipment

Summary

Marine LNG gas station is the service place that built in inland rivers or coastal zone to refuel fro LNG ship. It can be divided into 3 types as per different water area and shoreline environmental conditions, different model of station building:

1. The LNG filling station that built depends on wharf collectively called coastal base station, e.g. trestle bend wharf fixed station, bulkhead wharf fixed station.

2.The LNG filling station that built depends on pontoon collectively called pontoon station, e.g. pontoon wharf or pipe gallery type, independent pontoon type.

3.Mobile filling station is built depends on power driving vessel, which has the characteristic of mobile filling service.

5.1.1 Shore-based Type LNG station

Summary

Shore-based type LNG station consists of LNG cryogenic storage tank, cryogenic immersed pump skid, marine LNG dispenser, instrument wind system, PLC control system. Functions: unload, unload a ship, LNG filling for ships, metering etc. Modular design, high integration level, convenient and swift to install.

Key Parameter

|

Product Model |

YN-JYQ-01 |

|

|

Working Medium |

Liquefied Natural Gas(LNG) |

|

|

Tank Capacity |

60m3 |

120m3 |

|

NO.of pumps |

1 |

2 |

|

Discharge pumps |

340L/min |

680L/min |

|

Working Pressure |

1.2MPa |

|

|

NO.of LNG Dispenser |

1 |

2 |

|

Total Power |

15KW |

30KW |

|

Control Mode |

PLCFullAutomaticControl |

|

5.1.2 Pontoon type LNG Station

Summary

Pontoon type LNG station consists of cryogenic storage tank, storage tank ice chest (include cryogenic immersed pump), filling arm (filling hose), instrument wind system, security system. Functions: unload, unload a ship, LNG filling for ships, metering etc. Modular design, high integration level, convenient and swift to install.

Key Parameter

|

Product Model |

YN-CY-JYQ-01 |

|||

|

Working Medium |

Liquefied Natural Gas(LNG) |

|||

|

Storage Tank Capacity |

100m3 |

200m3 |

300m3 |

|

|

NO.of pumps |

2 |

3 |

||

|

Rated Working Pressure |

1.2MPa |

|||

|

Max.Pump Discharge |

680L/min |

1020L/min |

||

|

Total Power |

30KW |

45KW |

||

|

Control Mode |

PLC Full Automatic Control |

|||

5.2 Complete equipment for LNG fuel-driven vessel

5.2.1 LNG supply Equipment for Fuel Power-driven Vessel

Summary

LNG supply equipment consists of storage tank, storage tank ice chest, fuel gas doublewall pipe, ventilation system, instrument wind system. Function: filling and supply of storage tank, pressure regulating of storage tank, gas supply for engine, safety relief, mechanical ventilation etc. Safely and stably supply gas to natural gas engine and dynamo.

Key Parameter

|

Product Model |

YN-CY-S03 |

YN-CY-S05 |

YN-CY-S08 |

YN-CY-S10 |

|

Storage Tank Capacity |

3 m³ |

5 m³ |

8 m³ |

10 m³ |

|

Quantity of gas supply |

≤400Nm³/h |

|||

|

Working Pressure |

1.0 MPa |

|||

|

Design Pressure |

1.2 MPa |

|||

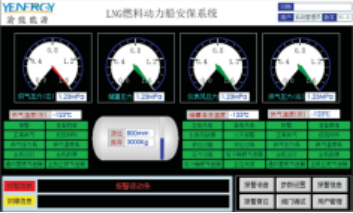

5.2.2 LNG Fuel Power-driven Vessel Security System

Summary

● The security system consists of engine room security control cabinet, driving console remote alarm board, filling LBZ. The safety system and control & monitoring system is mutual independence, safety system prior to control & monitoring system, system is of high security.

● The power supply of this system uses redundant design, main power supply and standby power supply are redundancy, the other power supply can supply power without closing down while one breaks down. The system equipped with UPS module and backup battery, and the backup battery can continuously supply power for 30 minutes.

● This system uses distributed design concept, the left and right control unit are respectively controlled by 2 sets independent control unit, and the security signal accesses to the safety system independent of control system. The controller of safety system uses the PLC controller with safety certificate, the complete system reaches SIL Ⅱ safety level.

● Each control unit with I/O module, it will not affect other control unit even if one breaks down, which minimizes risks.

● Each control unit equips with touch display screen, there is remote alarm display in the cab console, audio-visual display and easy operation.

● The system equips with wireless data remote transmission interface, which can upload equipment operational condition, ship location to shipowner information management platform, then the shipowner can view equipment operational condition, fuel consumption condition and ship navigation track etc, in real-time.

5.3 Ships Information Management Platform

Summary

With the increase of LNG vessels, the management platform with function of safety supervision and filling facility dispatching management is demanded. Therefore, our company develops the information management platform that applies to security supervision of gas storage, gas supply, gas use for LNG ships, ship location, filling facility intelligent dispatching management. It is available for security supervision and operation dispatching management of ships of marine bureau, shipowner and gas filling operating enterprise.

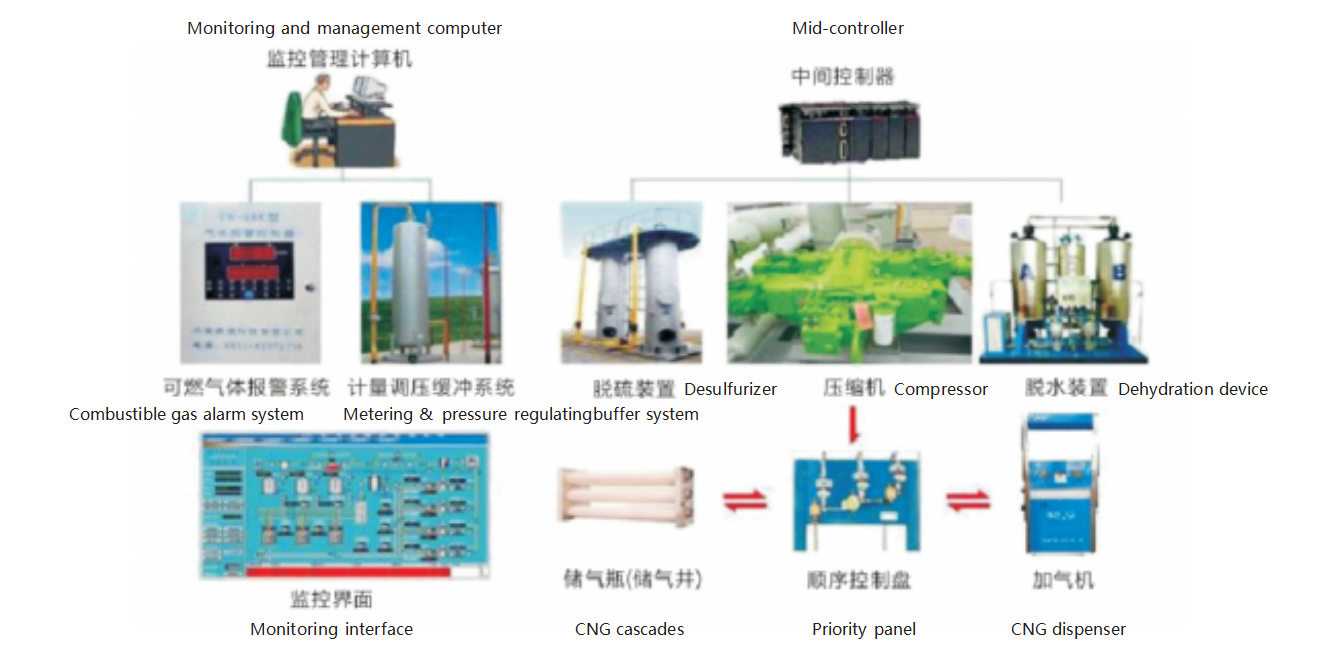

6.CNG gas station complete equipment

6.1 CNG dispenser

Summary

The general type intelligent CNG dispenser uses our company’s independent development high-performance military rank microprocessor control system, which is mainly used to meter CNG filling for CNG vehicle. The industry leading pressure intelligence computing function ensures one-time fully filling and preventing overfill. Scientific CNG filling speed control ensures the reliable control of CNG filling target pressure.

Our independent R&D microcomputer controller uses military rank electronic parts, and passes the harsh environmental suitability, electromagnetic compatibility and safety performance test, which ensures the reliability of microcomputer controller while the CNG dispenser runs under the complex operating environment. We own the proprietary intellectual property rights, there is no obstacle for technology upgrading and rebuilding in future.

Advantages

Industry-leading pressure control Modular design Proprietary intellectual property rights

Key Parameters

|

CNG Dispenser Series |

||

|

Basic type |

Massflow CNG dispenser |

Single-line single-hose,single-line dual-hose,single-line four-hose |

|

Dual-line single-hose,dual-line dual-hose,dual-line four-hose |

||

|

Three-line single-hose,three-line dual-hose,three-line four-hose |

||

|

Technical Parameters |

Applicable medium |

Compressed Natural Gas(CNG) |

|

Accurac ymeasuring |

±1.0% |

|

|

Range of flow |

(2-30)kg/min(3-40)Nm3/min |

|

|

Rated working pressure |

20MPa |

|

|

Max.working pressure |

25MPa |

|

|

Compressive strength |

37.5MPa |

|

|

Ambient temperature |

-40℃-+50℃ |

|

|

Explosive-proof grade |

Exdefbmb ⅡAT4Gb |

|

|

Power supply |

220V±15% 50Hz±1Hz |

|

|

Unit of measurement |

Kg/Nm³ |

|

|

Minimum scale reading |

0.01 |

|

|

Single counter range |

0~9999.99 |

|

|

Totalize range |

0~99999999.99 |

|

|

Rated power |

Single-hose:100W,dual-hose:200W,Four-hose:400W |

|

Main Function

Highlight backlight LCD, dual display unit price, CNG volume and sum

Safety protection function for overpressure, overflowing, anti-surge

Ultra-large capacity memory function, 20,000 CNG filling transactions can be saved while off-line, and supports inquiry and print historical data

Refuel by preset volume and sum

Fault self-service diagnostic function, automatic display fault code

Pressure temperature compensation

Breaking protection

Pressure discharge and blow-off

IC card auto settlement and management

Automatic filling pressure control, which assures take out CNG from storage system effectively

Data protection and data delay display when power failure

Display the recent CNG filling data

Monitor malfunction of mass flow meter and stop refueling while mass flow meter has malfunction

Gas leakage and gas lost protection, display alert information

Filter online cleaning function

Manual emergency shut-down valve

Bill printer

6.2 CNG filling/unloading column

Summary

CNG filling/unloading column uses high-performance industrial control microprocessing system, which is the metering equipment used in trade settlement of CNG main station or substation, and mainly filling/unloading & metering for CNG tank car.

Temperature compensation is available as it uses imported mass flow meter with temperature sensor, high accuracy pressure sensor assures the high accuracy metering.

Mass flow meter, manual ball valve, high pressure hose, quick coupling are imported from famous brand abroad.

Designed and manufactured by ourselves, the computer controller uses industrial grade electronic components, and it passed the test of harsh environmental suitability, electromagnetic compatibility and safety, which assures the reliability of computer controller in complex operating environment. With proprietary intellectual property rights, there is no any obstacle in technology upgrading and rebuilding in future.

Runner pipe path isΦ22x4, high pressure hose diameter is 25mm, maximum flow reaches 80kg/min.

Advantages

High accuracy of measuring、High reliability、Proprietary intellectual property rights、 Fast speed for filling

Main function

Safety protection function for overpressure, overflowing

Data protection and data delay display when power failure

Bulk-storage memory function, inquiry shift total volume and total totalizer

Refuel by preset volume and sum

Display the recent CNG filling data

Fault self-service diagnostic function, automatic display fault code

Pressure temperature compensation

Breaking protection

Manual emergency shut-down valve

IC card auto settlement and management (optional)

Bill printer

Data transmission commu

nication interface

Key Parameters

|

CNGFilling/Unloading Column Series |

||

|

Basic type |

CNG filling column |

Single-line single-hose,single-line dual-hose, dual-line single-hose,medium pressure CNG filling column |

|

CNG unloading column |

Single-line single-hose,single-line dual-hose |

|

|

Technical Parameters |

Applicable medium |

Compressed Natural Gas(CNG) |

|

Accuracy of measuring |

±1.0% |

|

|

Range of flow |

CNG filling column :(3-70)kg/min(3-80)m³/min CNG unloading column :(3-77)kg/min(3-90)m³/min |

|

|

Rated working pressure |

20MPa |

|

|

Max.working pressure |

25MPa |

|

|

Ambient temperature |

-40℃-+50℃ |

|

|

Explosive-proof grade |

Exdefbmb ⅡAT4Gb |

|

|

Power supply |

220V±15% 50Hz±1HZ |

|

|

Unit of measurement |

Kg/Nm³ |

|

|

Minimum scale reading |

0.01 |

|

|

Single counter range |

0~9999.99 |

|

|

Totalize range |

0~99999999.99 |

|

|

Rated power |

Single-hose:100W,dual-hose:200W |

|

7. Hydrogen Dispenser

Summary

The hydrogen dispenser is used to fill hydrogen for fuel cell car. Our hydrogen dispenser uses design of three-step control fuel strategy and multiple explosion-proof technical combination, to fill hydrogen to vehicle- mounted fuel cylinder automatically, energy-saving, safely, quick and reliable via data collection and calculation of controller.

Our hydrogen dispenser has the safety protection function of overpressure protection, environment temperature compensation, break away coupling protection and leakage alarm system etc. The independent R&D computer controller uses industrial grade electronic components, and it passed the test of harsh environmental suitability, electromagnetic compatibility and safety, which assures the reliability of microcomputer control system of hydrogen dispenser.

Key Technical Parameters

|

Measuring accuracy |

0.30% |

|

Refuel Pressure |

35MPa |

|

Max. Working Pressure |

42MPa |

|

Explosive-proof Grade |

Ex deibmbpx IIB+H2 T4 |

|

Refuel Speed |

>0.6kgH2/min |

8.Natural Gas Station Information Management Platform

8.1 LNG Station SCADA System

Summary

● Using SIEMENS PLC and industrial configuration software to collect, store, record, display, remote upload and monitor the data of LNG/L-CNG station equipment. Main equipment: field instrument, PLC control cabinet, frequency conversion power distribution cabinet, monitoring computer and alarm system.

● High automation: one-touch operation, the operators can skillfully operate this system through simple training, which can prevent the wrong operation causing damage to personnel and equipment.

● High safety: interlocking control of ESD alarm, combustible gas alarm, flame alarm, field equipment overtemperature and overpressure alarm etc.

● Real-time monitoring the electric current of running cryogenic immersed pump, the temperature of pump pool and the cross- pressure of pump, which will bring multi-protection to the pump and extend the service life of pump.

● Automatically switch constant frequency mode and frequency conversion mode of cryogenic immersed pump to meet the pressure demand of different technical modes.

● Control the automatic start-stop of cryogenic high-pressure plunger pump according to the pressure of gas storing device, which assures to supply stable pressure for CNG dispensers.

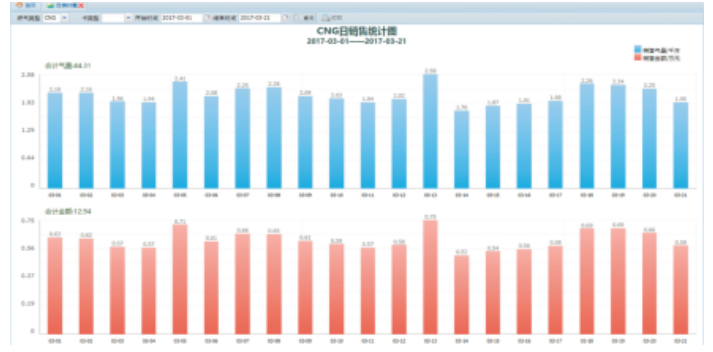

8.2 CNG station SCADA system

Summary

It usesindustrial grade universal configuration software and international advanced idea. As a real-time human-computer interface utility program generator, it has flexible configuration report function, support remote inquiry monitoring and voice alarm, provide common curve and multiple three-dimensional map.

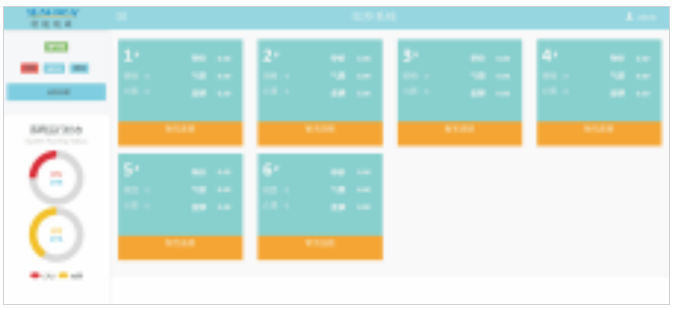

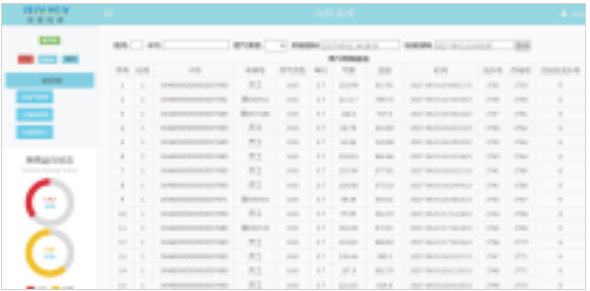

8.3. Intelligent network management system for CNG gas station

Summary

CNG gas station intelligent network management system uses modern computer networking technology and integrates intelligent IC card, electron, network and database technology, which provides CNG station with a easy management, stable performance, high efficiency & quickly response, resources sharinginformation management platform. Centralized management to each CNG gas station, and makes one-card, bank networking, third party payment such as wechat & alipay come true.

The CNG gas station intelligent network management system can be divided into 3 types: station level, region level and group level.

Station level management system: installed in the computers of CNG gas station, collecting data from CNG dispenser and storing them in the database, to inquire and statistic data for users.

Region level management system: makes the data exchange and data inquiry of multiple station level management systems in one region come true.Head office data center.

Group level centre management system: collecting data from multiple region level management system and provide data and decision-making basis for group management and control.

8.3.1 Station Level Management System

Summary

Equipped with data communication, display, report forms inquiry and message settings, the site management computer (including monitoring software and matched database) is installed in business hall of each gas station.

Main function

| Monitoring the data of CNG dispenser | Refueling bank water inquiring |

| Company vehicles refueling bank water inquiring | Authority management |

| CNG dispenser nozzle refueling bank water inquiring | Card NO. refueling bank water inquiring |

| Staff refueling bank water inquiring | Cash refueling bank water inquiring |

| Tally refueling bank water inquiring | System parameter settings |

| Day and month statistics of teams and groups, routes | Supporting multiple languages management, one-button switch of multi-l anguage |

| Interface parameter settings | Database backup/recover, log management |

| Teams and groups refueling bank water inquiring | Supporting large data volume concurrence |

| Vehicles refueling bank water inquiring | Supporting one nozzle one agreement, multiple nozzles one agreement |

| Vehicle model refueling bank water inquiring | Teams and groups information display: on duty, off duty |

| Blacklist and whitelist issuing | Data collection of multiple nozzles different agreement |

8.3.2 Center network management system

8.3.2.1 Center Web IC card Management System

Summary

Equipped with the functions of IC card basic information settings (pattern of consumption, vehicle type, unit price type), basic

rules settings, IC card information input (card NO., license plate NO., cylinder date etc.), IC card relevant information inquiry statistics etc.

|

|

Main Functions

| Build profile for vehicles | Vehicle type settings |

| Company information registration | Vehicle information registration |

| IC card recharge | Unlock “grey” IC card |

| IChange of IC card unit price grade | IC card recharge information inquiry |

| IC card summary information inquiry | IC card recharge information summary |

| Consumption patterns settings | Unit price grade settings |

| Driver information maintenance | IC card issuing |

| Cancel report and report the loss of IC card | Date change of IC card cylinder |

| IC card issued information inquiry | IC card account checking information inquiry |

| Information inquiry of report for loss | Authority management |

8.3.2.2 Center Data Inquiry System

Summary

This system is a B/S structure Internet access platform, which provides different inquiry function for different users without installing system.

Main functions

● Shift change statistics of each station or summary statistics of all stations, display the details of each shift in each station and support printing.

● Report form processing: summarizing the data from each station and provides various report forms.

● Right and power distribution: system decentralized management, different permission for different users, and only the person who has permissions can operate and use relevant function module.

● Local area network and entire network access is available, which is convenient for different functional department to inquiry management data (e.g. production Dept. financial Dept. management Dept. etc.)

● Function of consumption details and balance inquiry.

● Function of shift inquiry and shift accumulative statistics.

● Function of data audit and report forms printing.

8.4 Self-service recharge system

Summary

It supports Wechat, Alipay and cash payment, 24 hours unattended operation to lessen workloads, save labor cost and improve service quality. Elegant appearance and improve the image of gas station.

Main function

● 24 hours unattended operation for self-service recharge, credit for load and inquiry service.

● Identify cash automatically.

● Support third party payment such as wechat, Alipay.

● ATM style user interface, touch screen operation with voice prompt.

● Value-added services: traffic fine, gas fee, electric charge etc.

● Advertisement putting, information push.

Video Display

What Makes Betitles So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

Our Competitive Advantage

Based On Quality

All products undergo strict testing before leaving the factory, always adhering to the principle of quality first

6S Management

We use the 6S (Seiton, Seiso, Seiketsu, Shitsuke, Security) system to improve workshop efficiency and enhance quality output.

R&D Department

We have our own R&D department, constantly improving and expanding our supply range.

Innovation and one-stop service

We constantly innovate and strive to provide customers with one-stop services. We are good at marketing and help to seize good markets.

Certificate

All products are of high quality and have ISO9001 international quality system certification and safety control system certification.

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at +86-15610793856 +86-15610793896 or kari@jrcompressor.com salesmanager@jrcompressor.com , and we will respond to you within i hour.

Factory Environment

Our company covers an area of 92000㎡ including 25000㎡ office building, 38000㎡ workshop, 3000㎡ staff canteen and 6000㎡ dormitory and 20000㎡ public area.

Find the right compressor for you and get the best solution

Find the right compressor for you and get the best solution

Our equipment are widely used in natural gas, coal gas, oil field gas, rich gas, propylene, carbon dioxide, chlorine, dimethyl ether, ammonia, nitrogen, Freon, difluoroethane and other special industrial gases. It is widely used in the fields of pressure stabilization, compression and transportation in recovery, gas gathering, gas injection, line cleaning and petrochemical processes.

We provide 6 series of gas compressor and over 100 types, which has been exported to many countries: a. Liquefied gas series; b. Natural gas series; c. Natural gas high-pressure filling; d. Oil well gas, (dry gas, wet gas) casing gas, rich gas, and coal gas series; e. Chemical and industrial Gas series compressors; f. Engineering, air and high-pressure series compressors

Other Products

Our mainly products include Diaphragm compressor, piston compressor, centrifugal fan, hydrogen dispenser,etc. which can be used for the compression and transportation of inert gases, rare gases, flammable and explosive gases, corrosive gases, and high-pressure high-purity gases.