Product Series

Contact Us

Address

Third Floor, Office Building, No. 116 Wenshan West Road, Mishan Town, Wendeng District, Weihai City, Shandong Province,China

LNG station complete equipment

LNG station can be divided into 2 types: skid-mounted LNG station and stationary LNG station. Skid-mounted LNG station is to integrate storage tank, pump skid, PLC control system and LNG dispenser in one skid, which is convenient to transport the full station. Stationary LNG station is to install storage tank, pump skid, PLC control system and LNG dispenser in the station. Main equipment composition: cryogenic storage tank, LNG cryogenic immersed pump, LNG unloading skid, instrument wind system, PLC control system etc. Main function: LNG unloading, pressure regulating, LNG filling, metering etc. Main advantages: modular design, high integration level, convenient and efficient installation.

Keywords:

Category:

LNG station complete equipment

E-mail:

E-mail:

一、LNG station complete equipment

Summary

LNG station can be divided into 2 types: skid-mounted LNG station and stationary LNG station. Skid-mounted LNG station is to integrate storage tank, pump skid, PLC control system and LNG dispenser in one skid, which is convenient to transport the full station. Stationary LNG station is to install storage tank, pump skid, PLC control system and LNG dispenser in the station.

Main equipment composition: cryogenic storage tank, LNG cryogenic immersed pump, LNG unloading skid, instrument wind system, PLC control system etc. Main function: LNG unloading, pressure regulating, LNG filling, metering etc. Main

advantages: modular design, high integration level, convenient and efficient installation.

Main functions

Unloading: unload LNG from tank car to storage tank through self-pressurization and pump.

Refueling: refuel LNG to vehicle cylinder through cryogenic pump and LNG dispenser.

Pressure boosting: filling partial LNG into LNG storage tank after vaporized to meet tank setting value

Saturation regulating: pumping partial LNG to vaporizer from storage tank by LNG cryogenic pump, and return to the bottom of storage tank after vaporization, which increases the temperature of LNG storage tank thereby increase the storage tank pressure.

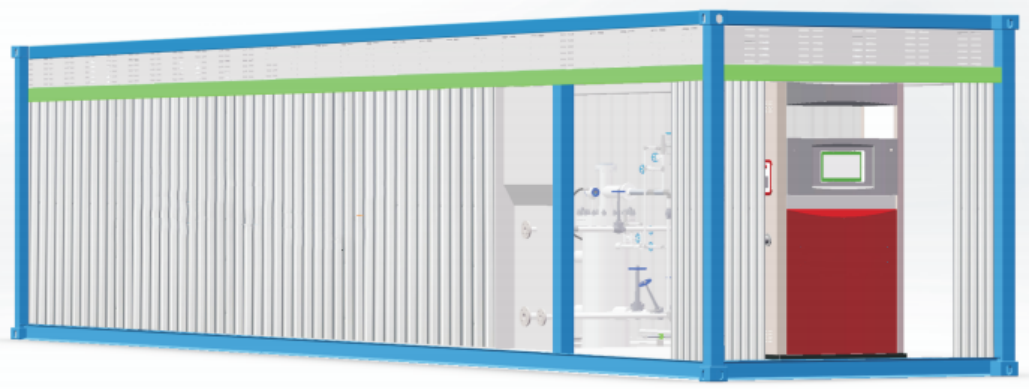

1.1 Skid-mounted LNG station

Summary

Skid-mounted LNG station is the complete LNG refueling system which assembled, tested and debugged in factory. This kind of system integrates LNG storage tank, LNG immersed pump, PLC control system and LNG dispenser in the skid, which is convenient to transport the full station. It can finish unloading, pressure regulating and refueling independently. It can be divided into 2 types: skid-mounted LNG station and container LNG station.

Key Parameter

Model | YN-JYQ-Q30A | YN-JYQ-Q60A |

Working medium | Liquefied Natural Gas(LNG) | |

Total volume of storagetank | 30m 3 | 60m3 |

Heatinsulation of storagetank | High vacuum twine / High vacuum pearlife padding | |

NO.of pumps | 1 unit | 2 units |

Max.discharge of pump | 340L/ min | 680L/ min |

Operating pressure | 1.6 Mpa | |

Measurin gaccuracy | ±1.0% | |

Pipeline design temperature | -196℃ | |

Total power | 15KW | 30KW |

Noise | ≤55dB | |

Explosive-proof grade | Exd ⅡBT4 | |

Control mode | PLC full automatic control | |

1.2 Stationary LNG station

Summar

Stationary LNG station is the LNG refueling system that is composed of 4 subsystems: LNG storage tank, LNG pump skid, LNG dispenser and PLC control cabinet. Each module finishes assembling, testing and debugging in factory. The station can be put into trial operation after each module connected, installed and debugged simply at site.

Key Parameter

Model | YN-JYQ-AD1A | YN-JYQ-AD2A |

Working medium | Liquefied Natural Gas( LNG) | |

NO.of pumps | 1unit | 2units |

Max.discharge of pump | 340L/ min | 680L/ min |

Operating pressure | 1.6 Mpa | |

Pipeline design temperature | -196℃ | |

Total power | 15KW | 30kW |

Noise | ≤55dB | |

Explosive-proof grade | Exd ⅡBT4 | |

Vaporizer | 300 + 150Nm3 | |

Dimension | 3500*2400*2400( mm ) | |

Control mode | PLC full automatic control | |

Model | YN-JYQ-AD1A | YN-JYQ-AD2A |

|  |

|  |

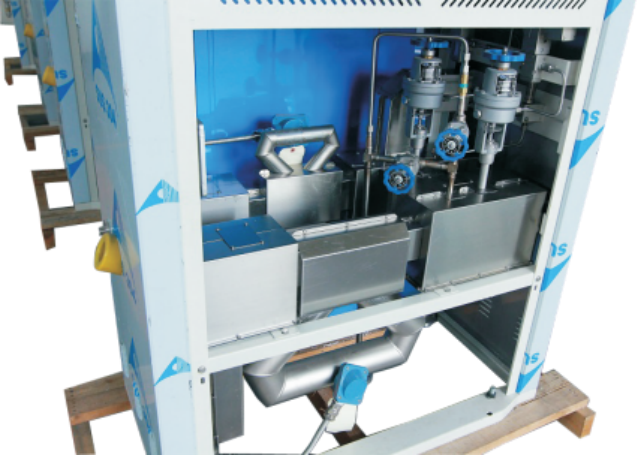

1.2.1 LNG Skid-mounted Pump

Summary

LNG pump skid is to integrate LNG cryogenic immersed pump, vacuum pump pool, vaporizer, vacuum pipeline and valves in the skid, which has functions of unloading, pressure regulating and refueling. Equip with safety precautions such as combustible gas detection, leakage alarm, emergency cut-off etc. Multiple unload mode: pump unload, self-pressurization unload, combined unload etc. Multiple functions: storage tank pressure boost, thermoregulation, instant refuel during unload, dual pump crossed standby application.Pump pool uses high vacuum twine heat insulation, inflow & outflow pipeline use PIR cold insulation mode, which keeps the cold loss to a minimum. Reuse the BOG in storage tank by our particular unloading equal pressure mode.

Advantages

High integration, easy installation, safe and reliable, advanced technological process, cold loss control.

|  |

1.2.2 LNG dispenser

Summary

Accuracy of measuring reaches ± 1%. Function of pipeline pressure limiting protection, which realizes overpressure protection through safety valve and pressure sensor. Advanced cold insulation technology - insulation treatment for all inner medium circulation pipelines (including mass flow meter), reduce BOG effectively. Repeated operation is unnecessary as liquid filling interval time is short, which will reduce gas filling waiting time. The operation mode single pumpdual dispensers and “ dual pumps four dispensers come true through interconnected control.

Summary Accuracy of measuring reaches ± 1%. Function of pipeline pressure limiting protection, which realizes overpressure protection through safety valve and pressure sensor. Advanced cold insulation technology - insulation treatment for all inner medium circulation pipelines (including mass flow meter), reduce BOG effectively. Repeated operation is unnecessary as liquid filling interval time is short, which will reduce gas filling waiting time. The operation mode single pumpdual dispensers and “ dual pumps four dispensers come true through interconnected control.

Advantages High accuracy of measuring、High security、Reasonable technological process Good thermal insulation properties, low loss. |

Main functions

Refuel by non-quantitative and preset volume

Measuring by mass and volume

Explosive-proof design: intrinsic safety and isolating safety

Breakaway coupling

Save data automatically after power cut, display data lingeringly

Display unit price, volume and sum with high light backlit LCD

IC card management, auto settlement and favorable unit price

Bill printer

Pressure temperature compensation function

Stop automatically after refueling completed

Data transmission communication interface

Key Parameter

LNG dispen serseries technical parameters | |

Applicable medium | Liquefied natural gas |

Range offlow | 3 ~80kg/min |

Accuracy of measuring | ±1.0% |

Working Pressure | 1.6 MPa |

Ambient temperature | -40℃-+55℃ |

Pipeline temperature | -196℃-+55℃ |

Ambient Humidity | ≤95% |

Ambient Atmosph ere | 86 ~ 110Kpa |

Unit of measurement | Kg、 L、 Nm3 |

Minimum scale reading | 0.01 |

Single counter Range | 0 ~9999.99 |

Totalize range | 99999999.99 |

Refueling Hose | 1 inch stainless steel flexible hose(4m/6m) |

Gas phase recovery hose | 1/2 inch stainless steel flexible hose(4m/6m) |

Filling nozzle | 1 inch special use for LNG dispenser |

Gas phase pipe joint | 1/2 inch quick coupling |

Power supply | 220V ±15% 50Hz ±1 HZ |

Explosive-proof grade | Complete Machineanti-explosion Exdefbmb ⅡAT4Gb |

Rated power | 200W |

Video Display

What Makes Betitles So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

Our Competitive Advantage

Based On Quality

All products undergo strict testing before leaving the factory, always adhering to the principle of quality first

6S Management

We use the 6S (Seiton, Seiso, Seiketsu, Shitsuke, Security) system to improve workshop efficiency and enhance quality output.

R&D Department

We have our own R&D department, constantly improving and expanding our supply range.

Innovation and one-stop service

We constantly innovate and strive to provide customers with one-stop services. We are good at marketing and help to seize good markets.

Certificate

All products are of high quality and have ISO9001 international quality system certification and safety control system certification.

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at +86-15610793856 +86-15610793896 or kari@jrcompressor.com salesmanager@jrcompressor.com , and we will respond to you within i hour.

Factory Environment

Our company covers an area of 92000㎡ including 25000㎡ office building, 38000㎡ workshop, 3000㎡ staff canteen and 6000㎡ dormitory and 20000㎡ public area.

Find the right compressor for you and get the best solution

Find the right compressor for you and get the best solution

Our equipment are widely used in natural gas, coal gas, oil field gas, rich gas, propylene, carbon dioxide, chlorine, dimethyl ether, ammonia, nitrogen, Freon, difluoroethane and other special industrial gases. It is widely used in the fields of pressure stabilization, compression and transportation in recovery, gas gathering, gas injection, line cleaning and petrochemical processes.

We provide 6 series of gas compressor and over 100 types, which has been exported to many countries: a. Liquefied gas series; b. Natural gas series; c. Natural gas high-pressure filling; d. Oil well gas, (dry gas, wet gas) casing gas, rich gas, and coal gas series; e. Chemical and industrial Gas series compressors; f. Engineering, air and high-pressure series compressors

Other Products

Our mainly products include Diaphragm compressor, piston compressor, centrifugal fan, hydrogen dispenser,etc. which can be used for the compression and transportation of inert gases, rare gases, flammable and explosive gases, corrosive gases, and high-pressure high-purity gases.