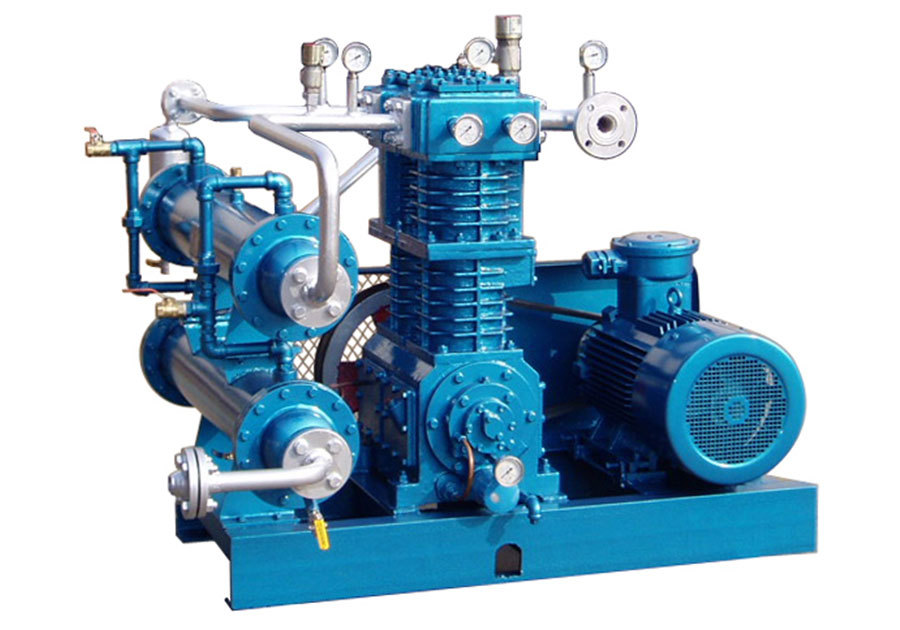

newest biogas compressor

Release time:

Aug 14,2025

Source:

Working principle

Biogas comes from landfill fermentation, food waste disposal and other sources. The main content of biogas is methane, carbon dioxide, and other relatively low content media. The biogas can be pressurized by a compressor and loaded into trucks to be supplied to users.

Main Specifications

| Structural type | Vertical (Z), Angular (V) |

| Suction pressure | 0~0.2MPa |

| Discharge pressure | 0.45~4.5MPa |

| Flow range | 50~700NM3/h |

| Motor power | 4~30kw |

| Cooling Method | Air or Water Cooling |

| Application | Biogas sources mainly include landfill fermentation, catering waste treatment and other ways, which can be loaded into vehicles to supply users with biogas through compressor pressurization |

Technical parameters and specifications

| S/N | Model | Gas | Inlet pressure (Mpa) | Outlet Pressure (MPa) | Flow (Nm³/h) |

| 1 | VW-7/1-45 | Biogas Compressor | 0.1 | 4.5 | 700 |

| 2 | VW-3.5/1-45 | 0.1 | 4.5 | 350 | |

| 3 | ZW-0.85/0.16-16 | 0.016 | 1.6 | 50 | |

| 4 | VW-5/1-45 | 0.1 | 4.5 | 500 | |

| 5 | VW-5.5/4.5 | Atm | 0.45 | 280 | |

| 6 | ZW-0.8/2-16 | 0.2 | 1.6 | 120 |

The biogas compressor is an essential component for optimizing biogas production and utilization. Designed to handle corrosive and moisture-rich gases, this compressor ensures efficient compression of biogas for storage or further processing. Its robust construction and advanced sealing technology prevent leaks, maximizing safety and performance. Whether for agricultural, industrial, or waste treatment applications, this biogas compressor delivers reliable operation under demanding conditions.

Equipped with high-efficiency motors and energy-saving features, our biogas compressor reduces operational costs while maintaining consistent output. The system supports variable flow rates, making it adaptable to fluctuating biogas production levels. Additionally, its low-maintenance design minimizes downtime, ensuring long-term reliability. This makes it an ideal choice for biogas plants seeking cost-effective and sustainable solutions.

Safety is a top priority, and our biogas compressor incorporates multiple protective mechanisms, including pressure relief valves and temperature monitoring. These features prevent overheating and over-pressurization, safeguarding both equipment and personnel. The compressor is also compatible with biogas purification systems, enabling seamless integration into existing setups.

With customizable options available, our biogas compressor can be tailored to meet specific project requirements. From small-scale farms to large industrial facilities, this compressor enhances biogas efficiency and usability. Invest in a high-performance biogas compressor to boost your renewable energy operations today.

Related news

Why Choose a Diaphragm Compressor for Your Industrial Applications?

Why Choose a Diaphragm Compressor for Your Industrial Applications? In the realm of industrial applications, selecting the right compressor can significantly impact operational efficiency and overall productivity. Among various options available in the market, diaphragm compressors have gained considerable attention. This article explores the reasons why diaphragm compressors stand out as an excel

Understanding Diaphragm Compressors: Key Insights for Manufacturing and Processing

Diaphragm compressors are specialized devices used to compress gases for a variety of applications in the manufacturing and processing industry. Unlike traditional piston or rotary compressors, diaphragm compressors utilize a flexible diaphragm to create a sealed chamber that compresses the gas. This mechanism allows for increased efficiency and the ability to handle gases that are corrosive or re

Unlocking Efficiency: The Role of Diaphragm Compressors in Modern Manufacturing

Unlocking Efficiency: The Role of Diaphragm Compressors in Modern Manufacturing Manufacturing industries around the world are continually seeking innovative solutions to enhance productivity and efficiency. One technology that has emerged as a game-changer in this quest is the **diaphragm compressor**. These compressors offer unique advantages that set them apart from traditional air compressors,

Understanding Hydraulic Hydrogen Compressors: A Key Component in Efficient Hydrogen Production

Hydraulic hydrogen compressors are specialized devices designed to compress hydrogen gas using hydraulic systems. These compressors play a crucial role in various applications, particularly in the fields of energy production, chemical processing, and even in fuel cell technology. The process of compressing hydrogen is essential for storage and transportation, as hydrogen is typically stored under

Unlocking Efficiency: The Role of a Hydraulic Hydrogen Compressor in Manufacturing

Unlocking Efficiency: The Role of a Hydraulic Hydrogen Compressor in Manufacturing Table of Contents 1. Introduction to Hydraulic Hydrogen Compressors 2. Understanding the Importance of Hydrogen in Manufacturing 2.1 Why Hydrogen is Gaining Traction 2.2 Applications of Hydrogen in Various Industries 3. How Hydraulic Hydrogen Compressors Work 3.1 The Mechanism Behind Hydraulic Compress

Understanding Hydraulic Hydrogen Compressors: Essential Insights for the Manufacturing Industry

Hydraulic hydrogen compressors are specialized machines designed to compress hydrogen gas to high pressures, making it suitable for various applications in the manufacturing sector. Hydrogen is increasingly being recognized as a clean energy source, and its efficient storage and transportation are crucial for utilizing its potential. Hydraulic compressors play a vital role in this process, particu