Product Series

Contact Us

Address

Third Floor, Office Building, No. 116 Wenshan West Road, Mishan Town, Wendeng District, Weihai City, Shandong Province,China

Marine LNG complete equipment

Marine LNG gas station is the service place that built in inland rivers or coastal zone to refuel fro LNG ship. It can be divided into 3 types as per different water area and shoreline environmental conditions, different model of station building: 1. The LNG filling station that built depends on wharf collectively called coastal base station, e.g. trestle bend wharf fixed station, bulkhead wharf fixed station. 2.The LNG filling station that built depends on pontoon collectively called pontoon station, e.g. pontoon wharf or pipe gallery type, independent pontoon type. 3.Mobile filling station is built depends on power driving vessel, which has the characteristic of mobile filling service.

Keywords:

Category:

LNG station complete equipment

E-mail:

E-mail:

Marine LNG complete equipment

5.1 Marine LNG complete equipment

Summary

Marine LNG gas station is the service place that built in inland rivers or coastal zone to refuel fro LNG ship. It can be divided into 3 types as per different water area and shoreline environmental conditions, different model of station building:

1. The LNG filling station that built depends on wharf collectively called coastal base station, e.g. trestle bend wharf fixed station, bulkhead wharf fixed station.

2.The LNG filling station that built depends on pontoon collectively called pontoon station, e.g. pontoon wharf or pipe gallery type, independent pontoon type.

3.Mobile filling station is built depends on power driving vessel, which has the characteristic of mobile filling service.

5.1.1 Shore-based Type LNG station

Summary

Shore-based type LNG station consists of LNG cryogenic storage tank, cryogenic immersed pump skid, marine LNG dispenser, instrument wind system, PLC control system. Functions: unload, unload a ship, LNG filling for ships, metering etc. Modular design, high integration level, convenient and swift to install.

Key Parameter

Product Model | YN-JYQ-01 | |

Working Medium | Liquefied Natural Gas(LNG) | |

Tank Capacity | 60m³ | 120m³ |

NO.of pumps | 1 | 2 |

Discharge pumps | 340L/min | 680L/min |

Working Pressure | 1.2MPa | |

NO.of LNG Dispenser | 1 | 2 |

Total Power | 15KW | 30KW |

Control Mode | PLCFullAutomaticControl | |

|  |

5.1.2 Pontoon type LNG Station

Summary

Pontoon type LNG station consists of cryogenic storage tank, storage tank ice chest (include cryogenic immersed pump), filling arm (filling hose), instrument wind system, security system. Functions: unload, unload a ship, LNG filling for ships, metering etc. Modular design, high integration level, convenient and swift to install.

Key Parameter

Product Model | YN-CY-JYQ-01 | |||

Working Medium | Liquefied Natural Gas(LNG) | |||

Storage Tank Capacity | 100m³ | 200m³ | 300m³ | |

NO.of pumps | 2 | 3 | ||

Rated Working Pressure | 1.2MPa | |||

Max.Pump Discharge | 680L/min | 1020L/min | ||

Total Power | 30KW | 45KW | ||

Control Mode | PLC Full Automatic Control | |||

|  |

|

5.2 Complete equipment for LNG fuel-driven vessel

5.2.1 LNG supply Equipment for Fuel Power-driven Vessel

Summary

LNG supply equipment consists of storage tank, storage tank ice chest, fuel gas doublewall pipe, ventilation system, instrument wind system. Function: filling and supply of storage tank, pressure regulating of storage tank, gas supply for engine, safety relief, mechanical ventilation etc. Safely and stably supply gas to natural gas engine and dynamo.

Key Parameter

Product Model | YN-CY-S03 | YN-CY-S05 | YN-CY-S08 | YN-CY-S10 |

Storage Tank Capacity | 3 m³ | 5 m³ | 8 m³ | 10 m³ |

Quantity of gas supply | ≤400Nm³/h | |||

Working Pressure | 1.0 MPa | |||

Design Pressure | 1.2 MPa | |||

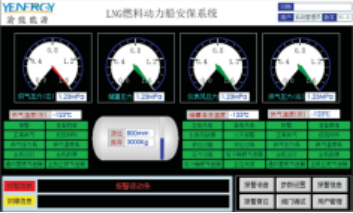

5.2.2 LNG Fuel Power-driven Vessel Security System

Summary

The security system consists of engine room security control cabinet, driving console remote alarm board, filling LBZ. The safety system and control & monitoring system is mutual independence, safety system prior to control & monitoring system, system is of high security.

The power supply of this system uses redundant design, main power supply and standby power supply are redundancy, the other power supply can supply power without closing down while one breaks down. The system equipped with UPS module and backup battery, and the backup battery can continuously supply power for 30 minutes.

This system uses distributed design concept, the left and right control unit are respectively controlled by 2 sets independent control unit, and the security signal accesses to the safety system independent of control system. The controller of safety system uses the PLC controller with safety certificate, the complete system reaches SIL Ⅱ safety level.

Each control unit with I/O module, it will not affect other control unit even if one breaks down, which minimizes risks.

Each control unit equips with touch display screen, there is remote alarm display in the cab console, audio-visual display and easy operation.

The system equips with wireless data remote transmission interface, which can upload equipment operational condition, ship location to shipowner information management platform, then the shipowner can view equipment operational condition, fuel consumption condition and ship navigation track etc, in real-time.

| |

|

5.3 Ships Information Management Platform

Summary

With the increase of LNG vessels, the management platform with function of safety supervision and filling facility dispatching management is demanded. Therefore, our company develops the information management platform that applies to security supervision of gas storage, gas supply, gas use for LNG ships, ship location, filling facility intelligent dispatching management. It is available for security supervision and operation dispatching management of ships of marine bureau, shipowner and gas filling operating enterprise.

Video Display

What Makes Betitles So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

Our Competitive Advantage

Based On Quality

All products undergo strict testing before leaving the factory, always adhering to the principle of quality first

6S Management

We use the 6S (Seiton, Seiso, Seiketsu, Shitsuke, Security) system to improve workshop efficiency and enhance quality output.

R&D Department

We have our own R&D department, constantly improving and expanding our supply range.

Innovation and one-stop service

We constantly innovate and strive to provide customers with one-stop services. We are good at marketing and help to seize good markets.

Certificate

All products are of high quality and have ISO9001 international quality system certification and safety control system certification.

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at +86-15610793856 +86-15610793896 or kari@jrcompressor.com salesmanager@jrcompressor.com , and we will respond to you within i hour.

Factory Environment

Our company covers an area of 92000㎡ including 25000㎡ office building, 38000㎡ workshop, 3000㎡ staff canteen and 6000㎡ dormitory and 20000㎡ public area.

Find the right compressor for you and get the best solution

Find the right compressor for you and get the best solution

Our equipment are widely used in natural gas, coal gas, oil field gas, rich gas, propylene, carbon dioxide, chlorine, dimethyl ether, ammonia, nitrogen, Freon, difluoroethane and other special industrial gases. It is widely used in the fields of pressure stabilization, compression and transportation in recovery, gas gathering, gas injection, line cleaning and petrochemical processes.

We provide 6 series of gas compressor and over 100 types, which has been exported to many countries: a. Liquefied gas series; b. Natural gas series; c. Natural gas high-pressure filling; d. Oil well gas, (dry gas, wet gas) casing gas, rich gas, and coal gas series; e. Chemical and industrial Gas series compressors; f. Engineering, air and high-pressure series compressors

Other Products

Our mainly products include Diaphragm compressor, piston compressor, centrifugal fan, hydrogen dispenser,etc. which can be used for the compression and transportation of inert gases, rare gases, flammable and explosive gases, corrosive gases, and high-pressure high-purity gases.