Product Series

Contact Us

Address

Third Floor, Office Building, No. 116 Wenshan West Road, Mishan Town, Wendeng District, Weihai City, Shandong Province,China

LPG unloading Compressor

The product is mainly used for unloading, loading, dumping, residual gas recovery and residual liquid recovery of liquefied petroleum gas/carbon 4, propylene and liquid ammonia.

Category:

Piston Compressor

E-mail:

E-mail:

LPG Compressor

Working principle

This series of oil-free lubrication compressor is one of the first products produced by our factory in China. The product has low rotational speed, high strength of components and is characterized by smooth operation, long service life and easy maintenance. Among them, ZW series compressor is in the form of unit. It integrates compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, check valve, explosion-proof motor and chassis. It is characterized by small volume, light weight, low noise, good sealing, easy installation and easy operation.

The product is mainly used for unloading, loading, dumping, residual gas recovery and residual liquid recovery of liquefied petroleum gas/carbon 4, propylene and liquid ammonia. It is widely used in gas, chemical, energy and other industries, and is the key equipment for gas, chemical, energy and other industries.

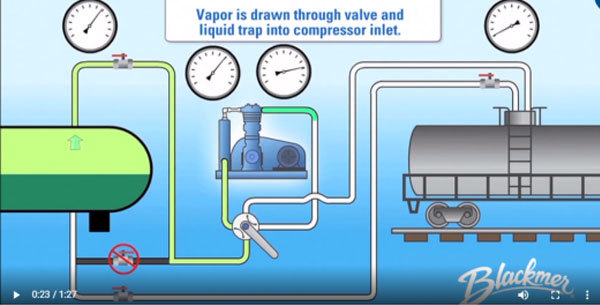

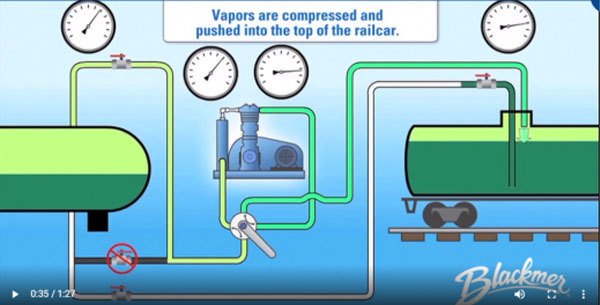

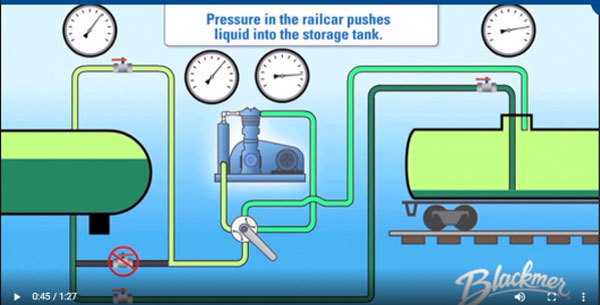

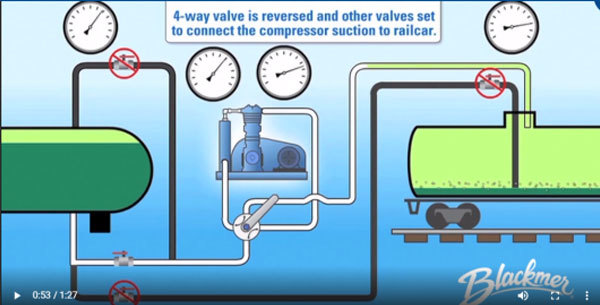

Note: In the process of unloading, the compressor pressurizes the gas from the storage tank and then presses it into the tanker through the gas-phase pipeline, and presses the liquid from the tanker to the storage tank through the pressure difference of the gas-phase in order to complete the unloading process. When the gas phase is pressurized, the temperature of the gas phase will rise, and at this time there is no need for forced cooling, because if the gas phase is compressed and then cooled, it is easy to liquefy, and it is difficult to build up the differential pressure of the gas phase, which is not conducive to the replacement of the gas phase with the liquid phase, in short, it will cause the unloading process to be prolonged. If residual gas recovery is required, during the residual gas recovery operation, a cooler can be selected to forcefully cool the gas phase so that the residual gas can be recovered as soon as possible.

The loading process is the opposite of the unloading process.

Main Specifications

|

Structural type |

Vertical (Z), Angular (V) |

| Discharge pressure | 1.6,2.4Mpa |

| Flow range | 0.25~8M3/min |

| Motor power | 4~110kw |

|

Application |

Mainly used for LPG/C4, propylene, liquid ammonia unloading, loading, tank pouring, residual gas recovery and residual liquid recovery. Widely used in gas, chemical, energy and other industries, is the key equipment of gas, chemical, energy and other industries. |

LPG/Carbon 4 loading and unloading compressor

| Serial No. | Model Number | Motor Power(kw) | Dimension(mm) | Loading and unloading(t/h) | |||

| 1 | ZW-0.25/10-16 | 4 | 1000x710×865 | ~5.5 | |||

| 2 | ZW-0.4/10-16 | 5.5 | 1000×710x865 | ~9 | |||

| 3 | ZW-0.5/10-16 | 7.5 | 1000×710x865 | ~11 | |||

| 4 | ZW-0.6/10-16 | 7.5 | 1000x710×865 | ~13 | |||

| 5 | ZW-0.8/10-16 | 11 | 1000x710x865 | ~17.5 | |||

| 6 | ZW-1.1/10-16 | 15 | 1000x710×865 | ~24 | |||

| 7 | ZW-1.35/10-16 | 18.5 | 1000x710×865 | ~30 | |||

| 8 | ZW-1.6/10-16 | 22 | 1400x900x1180 | ~35 | |||

| 9 | ZW-2.0/10-16 | 30 | 1400×900x1180 | ~45 | |||

| 10 | ZW-2.5/10-16 | 37 | 1400×900×1180 | ~55 | |||

| 11 | ZW-3.0/10-16 | 45 | 1400×900×1180 | ~65 | |||

| 12 | ZW-4.0/10-16 | 55 | 1400×900x1180 | ~85 | |||

| 13 | ZW-5.0/10-16 | 75 | 2000×1700×1400 | ~110 | |||

| 14 | ZW-6.0/10-16 | 90 | 2000x1700x1400 | ~130 | |||

| 15 | ZW-8.0/10-16 | 110 | 2000x1700x1400 | ~174 | |||

| 16 | ZW-0.75/10-16 | 11 | 1450×800×1300 | ~16.3 | |||

| 17 | ZW-1.5/10-16 | 22 | 1860×1680×930 | ~32.6 | |||

Inlet pressure:≤10MPa Discharge pressure:s16MPa

Differential pressure: 0.6MPa Instantaneous pressure ratio: ≤6 Cooling method: air-cooled

The unloading volume is calculated according to the feed pressure of 1.0MPa, discharge pressure of 1.6MPa, feed temperature of 40℃, and liquid density of liquefied gas of 582.5kg/m3, and it will be changed accordingly when the working brother changes.

The unloading volume will be changed accordingly, for reference only.

Compressor for loading and unloading of propylene

| Serial No. | Model Number | Motor Power(kw) | Dimension(mm) | Loading and unloading (t/h) | |||

| 1 | ZW-0.6/16-24 | 11 | 1000x680x870 | ~15 | |||

| 2 | ZW-0.8/16-24 | 15 | 1000×680×870 | ~20 | |||

| 3 | ZW-1.0/16-24 | 18.5 | 1000×680×870 | ~25 | |||

| 4 | ZW-1.5/16-24 | 30 | 1400×900×1180 | ~36 | |||

| 5 | ZW-2.0/16-24 | 37 | 1400×900×1180 | ~50 | |||

| 6 | ZW-2.5/16-24 | 45 | 1400×900x1180 | ~60 | |||

| 7 | ZW-3.0/16-24 | 55 | 1600×1100×1250 | ~74 | |||

| 8 | ZW-4.0/16-24 | 75 | 1600×1100×1250 | ~98 | |||

| 9 | VW-6.0/16-24 | 132 | 2400x1700x1550 | ~147 | |||

Inlet pressure:≤10MPa Discharge pressure:s16MPa

Differential pressure: 0.6MPa Instantaneous pressure ratio: ≤6 Cooling method: air-cooled

The unloading volume is calculated according to the feed pressure of 1.0MPa, discharge pressure of 1.6MPa, feed temperature of 40℃, and liquid density of liquefied gas of 582.5kg/m3, and it will be changed accordingly when the working brother changes.

The unloading volume will be changed accordingly, for reference only.

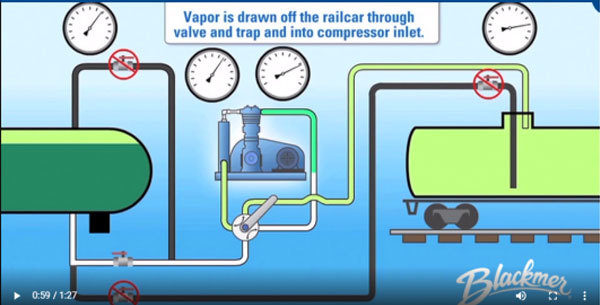

LEQUID TRANSFER AND VAPOR RECOVERY PROCESS

|

|

|

|

|

|

The LPG Unloading Compressor is a critical piece of equipment designed for the efficient unloading of liquefied petroleum gas (LPG) from tanker ships or storage tanks to processing plants or storage facilities. Engineered to handle the high pressures and low temperatures associated with LPG, these compressors ensure safe and reliable transfer of gas, minimizing product loss and ensuring optimal flow rates.

Built with durable, corrosion-resistant materials, the LPG Unloading Compressor is capable of withstanding the harsh conditions of LPG transport and unloading. Its robust design allows for continuous operation with minimal maintenance, reducing downtime and increasing operational efficiency. These compressors are available in various configurations to meet specific operational requirements, including single-stage or multi-stage models, depending on the pressure and flow demands.

Equipped with advanced safety features, such as pressure relief valves and temperature monitoring systems, LPG unloading compressors are designed to provide secure, smooth operation in compliance with industry standards. Whether for marine or land-based LPG unloading applications, these compressors play a vital role in ensuring the safe, fast, and cost-effective transfer of LPG.

Video Display

LPG Recirculating Compressor video

What Makes Betitles So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

Our Competitive Advantage

Based On Quality

All products undergo strict testing before leaving the factory, always adhering to the principle of quality first

6S Management

We use the 6S (Seiton, Seiso, Seiketsu, Shitsuke, Security) system to improve workshop efficiency and enhance quality output.

R&D Department

We have our own R&D department, constantly improving and expanding our supply range.

Innovation and one-stop service

We constantly innovate and strive to provide customers with one-stop services. We are good at marketing and help to seize good markets.

Certificate

All products are of high quality and have ISO9001 international quality system certification and safety control system certification.

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at +86-15610793856 +86-15610793896 or kari@jrcompressor.com salesmanager@jrcompressor.com , and we will respond to you within i hour.

Factory Environment

Our company covers an area of 92000㎡ including 25000㎡ office building, 38000㎡ workshop, 3000㎡ staff canteen and 6000㎡ dormitory and 20000㎡ public area.

Find the right compressor for you and get the best solution

Find the right compressor for you and get the best solution

Our equipment are widely used in natural gas, coal gas, oil field gas, rich gas, propylene, carbon dioxide, chlorine, dimethyl ether, ammonia, nitrogen, Freon, difluoroethane and other special industrial gases. It is widely used in the fields of pressure stabilization, compression and transportation in recovery, gas gathering, gas injection, line cleaning and petrochemical processes.

We provide 6 series of gas compressor and over 100 types, which has been exported to many countries: a. Liquefied gas series; b. Natural gas series; c. Natural gas high-pressure filling; d. Oil well gas, (dry gas, wet gas) casing gas, rich gas, and coal gas series; e. Chemical and industrial Gas series compressors; f. Engineering, air and high-pressure series compressors

Other Products

Our mainly products include Diaphragm compressor, piston compressor, centrifugal fan, hydrogen dispenser,etc. which can be used for the compression and transportation of inert gases, rare gases, flammable and explosive gases, corrosive gases, and high-pressure high-purity gases.